Features & Benefits

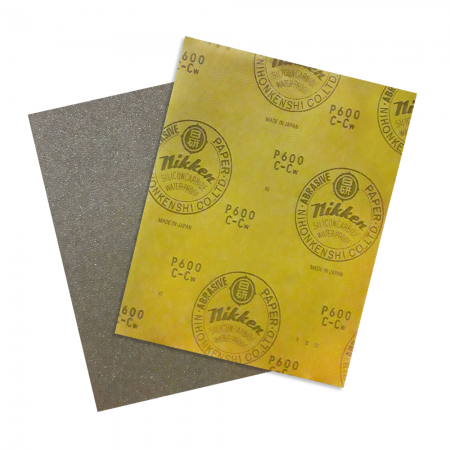

Fast dry time. Fast cure.

Sparko Surface Coatings values the amount of time it takes to create quality finishes. Special thinners are formulated methodically to save up production and lead time while providing optimum fast drying time for Nitrocellulose and Vinyl Finishes without compromising the quality, durability, and aesthetic in the process.

Quick build up. Minimal paint consumption.

Sparko provides a wide array of protective surface coatings that are carefully processed during production such that binders contain high solid content of film-forming components essential for quality finishes. This entails fast bulk up of protective film utilizing without consuming too much paint in the least amount of steps available.

Cost efficient. Cost savings.

Sparko Surface Coatings observes the “Sparko Standard” when accomplishing quality finishes on wood substrates. It involves lowering the amount of steps and consumption of paint by maximizing the high solid content characteristics of the binders. Basically, customers obtain significant savings in return without conceding the quality of the finish.

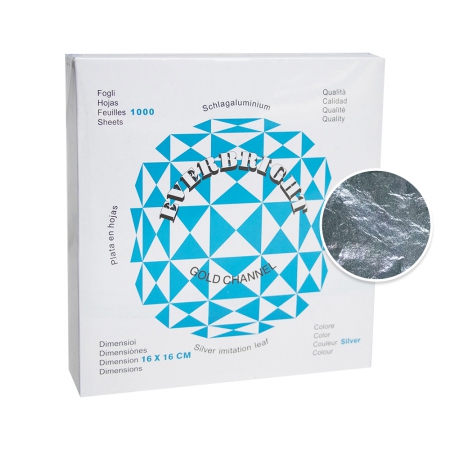

Detailed Variety of Finishing Products.

Quality finishes are not only achieved with high quality binders and excellent painting skills, it is accomplished by proper wood preparation techniques, specific thinner dilutions, stable colorants, and suitable binders for the type of application. Sparko offers a detailed outline of steps to achieve a desired finish as well as the appropriate list of finishing products to be used.